Rapid Mixer Granulator

Description

Rapid Mixer Granulator is designed to achieve in reducing processing time, more homogenous mixing consistent granules at lower operating cost and above all maintaining improved hygienic compliant to cGMP norm.

Synonyms: High Shear Mixer, High Shear Granulator

Application: Mixing different ingredients

Usage: Pharmaceutical, Nutritional, Biotech, Health Supplement, Food Product & Cosmetics

Versions: Stainless Steel 304, 316 and Mild Steel

Sailent Features:

- Better Productivity & short mixing granulation time.

- Uniform mixing & granulation.

- Bowl shape design to have no dead spaces.

- Less handling, more hygienic.

- Meets cGMP & FDA Norms.

- Contact parts are SS 316/316L.

Working Principal

Rapid Mixer Granulator working principles are based on two decisive factors essential for the intimate mixing system.

- Spinning close to bottom of mixing bowl.

- The impeller sets the entire mixture in whirling rising

tumbling motion ensuring a quick & even distribution of all dry components. This leads to an even distribution of all dry components & an even wetting of every granule. The large lumps occurred during wet mixing are broken up, by the strategically acted chopping tool rotating at 1440/2880 RPM.

The mixture can be discharged with the impeller running through outlet located on the side of the mixing bowl flush to the bottom. Easy accessibility for cleaning is guaranteed by the low profile. The mixing tool is easily removed from the drive shaft providing an unobstructed mixing area which may be cleaned very easily.

Control System:

- Manual Control - Process Timer for Main Motor & Chopper. AMP Meter for Main Motor of chopper. On/Off Push Button.

- Auto Control - PLC based with touch Screen and password level to feed the parameter of process for Wet / Dry Granulation.

- Pre stored process parameter will help to achieve consistent product quality.

- MMI (Touch Screen) for visualization of machine of specific process condition and data.

- PLC indicates: Visualization of Machine process condition & date. Alarm Signal & Fault Message

- SCADA package (optional)

Technical Specification

Gross Capacity in Liters |

Working Capacity in Liters |

Main Motor H.P. 750 / 1500 RPM |

Gear Box |

Chopper Motor H. P. 1500 / 2880 RPM |

Discharge Height |

Space Required L x b x h mm |

|---|---|---|---|---|---|---|

25 |

20 |

3 / 5 |

4” |

1.5 / 2 |

600 |

650 X 1200 X 1100 (1250) approx. |

100 |

80 |

7.5 / 15 |

5” |

2 / 3 |

780 |

1500 X 2200 X 1800 (2175)approx. |

150 |

120 |

7.5 / 15 |

5” |

3 / 5 |

780 |

1800 X 2500 X 1875 (2300)approx. |

250 |

200 |

25 / 30 |

7” |

3 / 5 |

1055 |

2000 X 2800 X 1920 (2450)approx. |

400 |

320 |

30 / 40 |

8” |

5 / 7.5 |

1200 |

2500 X 3000 X 2300 (3000)approx. |

600 |

480 |

40 / 50 |

10” |

5 / 7.5 |

1200 |

2700 X 3200 X 2300 (3000)approx. |

1000 |

600 |

63 / 85 |

12” |

10 / 15 |

1200 |

2900 X 2900 X 2500 (3200)approx. |

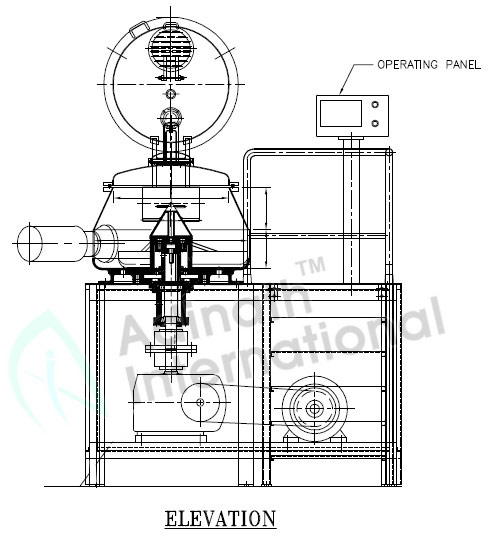

Drawing Layout of High Shear Mixer / Rapid Mixer Granulator

Optional:

- Flame Proof Motors & operating panel.

- Jacketed bowl for heating & cooling.

- Binder solution adding/spraying device.

- Cleaning in place (CIP) in built.

- IPC Lifter or Vacuum loading system for dust free material charging.

- Variable frequency drive for speed variation.

Documents & Services:

Complete set of documentation support in termsof DQ/ IQ/ OQ/ FAT/ SAT.

We provide necessary support for installationcommissioning and start-up of the machine at site.

Mixing Bowl & Cover

- Dome shaped bowl, which directs loose particles into whirling motion with help of impeller.

- Inclination of the mixing blades accelerates rising and tumbling motion of the product.

- Especially design chopper blades driven at high speed gives fast & even granulation.

- For the easy accessibility in cleaning the side

Products

- 100 Holes Capsule Filling Machine

- 300 Holes Capsule Filling Machine

- Automatic Capsule Filler

- Automatic Capsule Counting Machine

- Automatic Capsule Filling Machine

- Automatic Capsule Loader

- Automatic Capsule Orienter

- Capsule Counting Line

- Capsule Counting Machine

- Capsule Filling Line

- Capsule Filling Machine With Orienter

- Capsule Polishing Machine

- Double Cone Blender

- Fluid Bed Dryer

- Fully Automatic Encapsulation Machine

- Hand Operated Capsule Filling Machine

- Manual Capsule Counter

- Manual Capsule Filler

- Manual Capsule Filling Machine

- Manual Capsule Loader

- Manual Capsule Orienter

- Manual Encapsulation Machine

- Rapid Mixer Granulator

- Semi Automatic Capsule Filler

- Semi Automatic Capsule Filling Machine

- Tablet Counting Line