Fluid Bed Dryer

Description

Fluid Bed Dryer is ideal for production scale, pilot scale & R&D lab with latest Improvement in design makes this unit a truly versatile for Pharmaceuticals, Food, Dyestuff, Chemical, API, Bulk Drugs and Polymer Industries. All contact parts are made of SS 304 / 316 / 316L.

Synonyms: Fluidized bed dryer, Fluid Bed Processor

Application: Mixing different ingredients

Usage: Pharmaceutical, Nutritional, Biotech, Health Supplement, Food Product & Cosmetics

Versions: Stainless Steel 304, 316 and Mild Steel

Operation Process

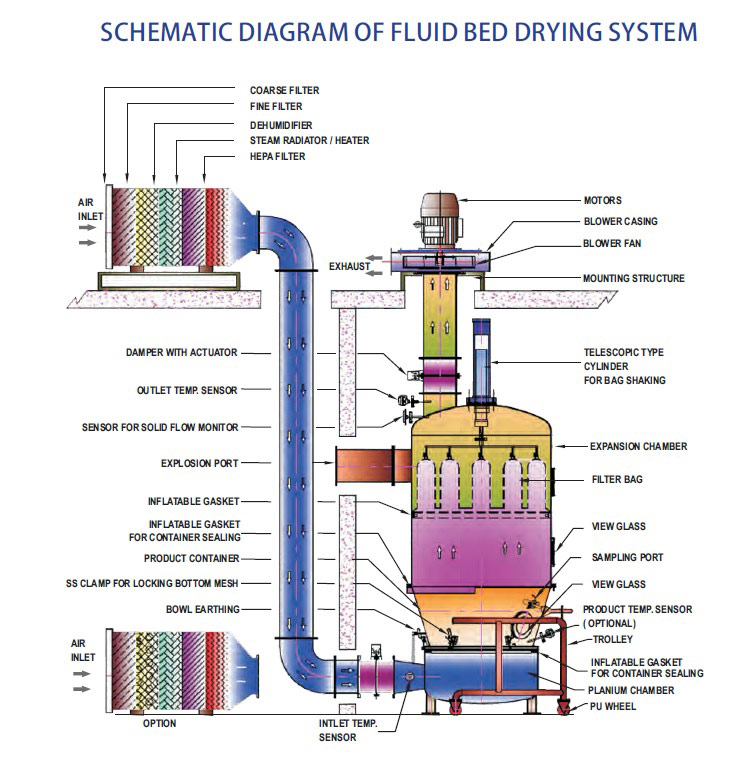

A Batch of product loaded into the material bowl is seated in the chamber & heated filtered air is drawn through the product. By this, the entire surface of individual particle is surrounded by the hot air thus achieving a homogeneous distribution of temperature and as a result of this, a rapid and careful drying down to the smallest- residual moisture. Escape of material from the granulation chamber is prevented by exhaust filters, which are periodically agitated or purged to reintroduce the collected material into the fluidized bed. The product can be cooled and the material container exchanged for the next batch.

The quantity of air is regulated by means of outlet air damper only.

Control System

Manual Control:

Inlet, Outlet, Bed (Optional) Temperature, Heating & Cooling Timer, Filter Bag Shaking On & Off Timer, Damper On & Off Timer.

Auto Control:

PLC based with touch Screen and password level to feed the parameter of process for Heating/Cooling & Bag Shaking Timing etc.

Pre stored process parameter will help to achieve consistent product quality.

MMI (Touch Screen) for visualization of machine of specific process condition and data.

PLC Indicates:

Visualization of Machine process condition & date.

Alarm Signal

Fault Message

SCADA Package

(optional)

Drying Time

The drying time depends on various factors such as physical properties of material, moisture content, type of moisture (free or inherent of water or crystallization) drying temperature etc. For example, the crystalline product can be dried faster than amorphous product containing same percentage of moisture at same temperature. Pharmaceutical granules & powder having approximately 20% to 25% moisture can be easily dried. Fluid Bed Dryers are normally supplied either with Electric Heating or with steam heating. However hot water / hot oil circulation system can also be installed.

Documentation

A complete documentation support in terms of DQ / IQ / OQ / FAT / SAT.

We provide necessary support for installation commissioning and start-up of the machine at site.

Technical Specification

| Capacity in Liters | 35 |

100 |

215 |

415 |

500 |

650 |

780 |

950 |

1200 |

1660 |

|---|---|---|---|---|---|---|---|---|---|---|

| Motor H. P. | 3 |

5 |

10 |

15 |

20 |

20 |

25 |

30 |

40 |

50 |

| Heating Capacity in k ca/hr | 3650 |

11200 |

21600 |

75000 |

75000 |

85000 |

9500 |

105000 |

- |

- |

| Steam Consumption kg/hr @ 3 kg/cm² | 10 |

30 |

60 |

120 |

120 |

175 |

200 |

250 |

325 |

400 |

| Length approx. in mm | 750 |

1175 |

1435 |

1725 |

1775 |

1900 |

2125 |

2200 |

2300 |

2550 |

| Width approx. in mm | 750 |

950 |

1400 |

1475 |

1550 |

1850 |

1925 |

2000 |

2050 |

2250 |

| Height approx. in mm | 1900 |

2650 |

2975 |

3350 |

4325 |

3700 |

3850 |

4025 |

4250 |

4950 |

| Product Container Height approx. in mm | 550 |

825 |

1000 |

1075 |

1150 |

1150 |

1200 |

1350 |

1350 |

1575 |

Optional Features:

- Flame proof construction

- Extra product bowl

- Hepa Filter in AHU

- Differential pressure gauge for HEPA Filter

- Exhaust air filter section with

- EU7 Filter (Police Filter)

- Dehumidification system

- Butterfly Valve with positioner

- AC Frequency Drive

- PLC & SCADA System

- Air Velocity sensor

- Solid flow monitor

- Silencer

- Recommended Spares

- Inlet and exhaust duct

Products

- 100 Holes Capsule Filling Machine

- 300 Holes Capsule Filling Machine

- Automatic Capsule Filler

- Automatic Capsule Counting Machine

- Automatic Capsule Filling Machine

- Automatic Capsule Loader

- Automatic Capsule Orienter

- Capsule Counting Line

- Capsule Counting Machine

- Capsule Filling Line

- Capsule Filling Machine With Orienter

- Capsule Polishing Machine

- Double Cone Blender

- Fluid Bed Dryer

- Fully Automatic Encapsulation Machine

- Hand Operated Capsule Filling Machine

- Manual Capsule Counter

- Manual Capsule Filler

- Manual Capsule Filling Machine

- Manual Capsule Loader

- Manual Capsule Orienter

- Manual Encapsulation Machine

- Rapid Mixer Granulator

- Semi Automatic Capsule Filler

- Semi Automatic Capsule Filling Machine

- Tablet Counting Line